Since our first project in 1974, Brockenbrough has been planning, designing and inspecting Petroleum/Fuel receipt, storage, and distribution facilities for various branches of the U.S. Military throughout the world. We have performed hundreds of projects in 50 U.S. states, two U.S. territories, and 16 foreign countries on six continents. From massive fuel storage complexes in remote locations, to the systems that directly refuel our nations combat aircraft, let us make your job easier and safer by helping you with your next project.

- Facility Evaluation

- FACILITY PLANNING

- Tank & Piping Inspection & Integrity Assessment

- STORAGE TANKS

- Truck & Railcar Loading/Off-Loading

- PIPELINES

- MARINE LOADING/OFF-LOADING

- HYDRANT SYSTEMS

- SUPPORT FACILITIES

What is the mission of this facility? What does it need to meet its mission? What is the condition of the existing facility? What changes, upgrades, repairs and modifications need to be made to meet its mission. What needs to be done to meet new or revised codes, standards, and regulations? The team at Brockenbrough is an expert when it comes to asking and determining answers to these Fuel System questions. |

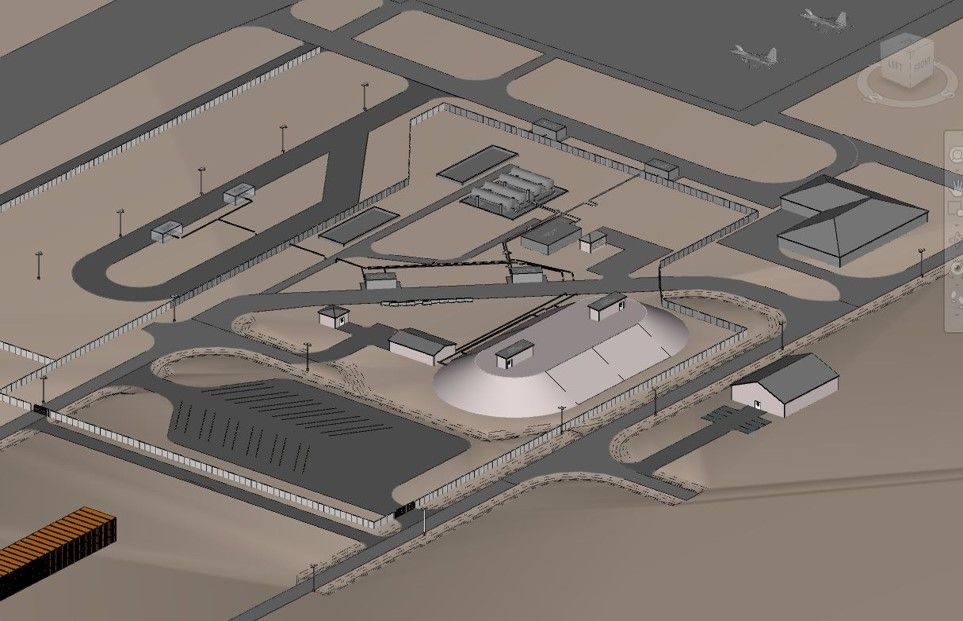

Brockenbrough has extensive experience with the planning of new fuel farms and terminals, aircraft direct fueling hydrant systems, marine loading and off-loading facilities, and truck off-loading and loading systems. Complying with current codes and environmental regulations is paramount to a well thought-out facility, along with the consideration of future growth. Application of proper planning techniques takes experience and knowledge of all aspects of fuel facility design, operation and maintenance. |

Assessing the condition and hydraulic integrity of fuel storage tanks and piping systems in accordance with the latest API and STI standards takes specific training, unique experience, state-of-the-art inspection equipment and detailed knowledge of the products and processes. Engineers at Brockenbrough are not only API and STI Certified Inspectors, they are tank and piping engineers as well. These engineers have the necessary qualifications and experience in designing, repairing, and inspecting chemical and fuel storage tanks and piping. |

Brockenbrough’s experience with petroleum and fuel facilities includes the design and repair of aboveground storage tanks (ASTs) and underground storage tanks (USTs). The team has experience in sizes up to 235,000 bbl (9,870,000 gallons) including working with field-erected, cut-and-cover tanks. Both ASTs and USTs are complex systems that must comply with all local, state and federal regulations. These systems may require leak detection, overfill protection, secondary containment, or other types of environmental protection devices. |

Every facility that stores and issues fuels has systems for receiving fuel and issuing it to mobile vehicles. Every facility has one or more systems for loading and/or off-loading over-the-road tank trucks, rail-cars and /or refueler trucks. These systems include equipment for filtering, pumping, metering, additizing, and transferring. Brockenbrough has designed dozens of these systems all over the world, including projects in the U.S., Central America, the Caribbean, Africa, Asia, and Europe. |

Pipelines are regulated, designed, constructed, and inspected to different standards than normal piping systems. The Brockenbrough team has a broad range of experience with pipelines, including design, inspection, and repair. The pipeline engineers and designers have experience and expertise in developing projects from concept to completion for fuel pipelines worldwide. Projects range in size from very small to the very large with constructed value up to fifty million dollars. |

Many large refineries and fuel storage depots have marine facilities for off-loading and loading bulk quantities of product. The pier structures and the mechanical and electrical equipment are specialized for the petroleum/fuel industry. The Brockenbrough team brings unique understanding of the types of tankers, the use of marine loading arms, loading and off-loading rates, and environmental regulations necessary to properly design these types of facilities. |

Aircraft hydrant fueling systems are used to directly refuel fixed and rotary wing aircraft. In all cases, fuel is delivered to the refueling positions via underground transfer pipelines from a remote pumphouse and tank farm. Brockenbrough has designed many of these systems at numerous locations around the world, including systems for large fixed wing aircraft, typically refueled while parked on an aircraft apron. When a quick turnaround is a mission requirement, aircraft are often refueled with their engines running at dedicated “hot pit refueling stations.” In these cases, the refueling equipment is fixed, not mobile. |

Fuel Farms are equipped with many facilities beyond those used to receive, store, transfer, and issue fuel. Brockenbrough is expert in facilities that support fueling operations such as operations buildings, fuels testing laboratories, contaminated fuel recovery systems, roads, site lighting, site fencing, and aircraft refueler truck parking. |